Rapid Flow-Based Peptide Synthesis

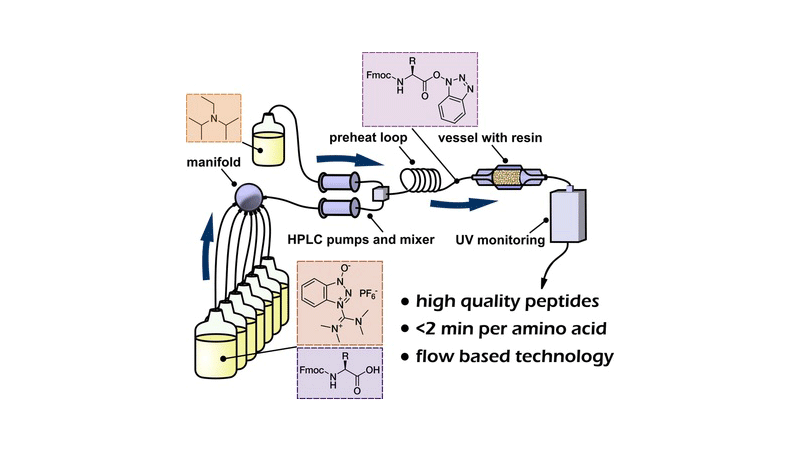

A flow-based solid-phase peptide synthesis methodology that enables the incorporation of an amino acid residue every 1.8 min under automatic control or every 3 min under manual control is described. This is accomplished by passing a stream of reagent through a heat exchanger into a low volume, low backpressure reaction vessel, and through a UV detector. These features enable continuous delivery of heated solvents and reagents to the solid support at high flow rate, thereby maintaining maximal concentration of reagents in the reaction vessel, quickly exchanging reagents, and eliminating the need to rapidly heat reagents after they have been added to the vessel. The UV detector enables continuous monitoring of the process. To demonstrate the broad applicability and reliability of this method, it was employed in the total synthesis of a small protein, as well as dozens of peptides. The quality of the material obtained with this method is comparable to that for traditional batch methods, and, in all cases, the desired material was readily purifiable by RP-HPLC. The application of this method to the synthesis of the 113-residue Bacillus amyloliquefaciens RNase and the 130-residue DARPin pE59 is described in the accompanying manuscript.

Pentelute Lab, MIT, Publications,

15749

portfolio_page-template-default,single,single-portfolio_page,postid-15749,bridge-core-3.0.1,qode-page-transition-enabled,ajax_fade,page_not_loaded,,paspartu_enabled,paspartu_on_top_fixed,paspartu_on_bottom_fixed,qode_grid_1200,qode_popup_menu_push_text_top,qode-theme-ver-28.7,qode-theme-bridge,disabled_footer_top,wpb-js-composer js-comp-ver-6.8.0,vc_responsive

Rapid Flow-Based Peptide Synthesis

Rapid Flow-Based Peptide Synthesis

Simon MD, Heider PL, Adamo A, Vinogradov AA, Mong SK, Li X, Berger T, Policarpo RL, Zhang C, Zou Y, Liao X, Spokoyny AM, Jensen KF, Pentelute BL., Chembiochem. 2014 Mar 21;15(5):713-20

Published

Online March 11 2014

Abstract

A flow-based solid-phase peptide synthesis methodology that enables the incorporation of an amino acid residue every 1.8 min under automatic control or every 3 min under manual control is described. This is accomplished by passing a stream of reagent through a heat exchanger into a low volume, low backpressure reaction vessel, and through a UV detector. These features enable continuous delivery of heated solvents and reagents to the solid support at high flow rate, thereby maintaining maximal concentration of reagents in the reaction vessel, quickly exchanging reagents, and eliminating the need to rapidly heat reagents after they have been added to the vessel. The UV detector enables continuous monitoring of the process. To demonstrate the broad applicability and reliability of this method, it was employed in the total synthesis of a small protein, as well as dozens of peptides. The quality of the material obtained with this method is comparable to that for traditional batch methods, and, in all cases, the desired material was readily purifiable by RP-HPLC. The application of this method to the synthesis of the 113-residue Bacillus amyloliquefaciens RNase and the 130-residue DARPin pE59 is described in the accompanying manuscript.

Category

2014, Publications